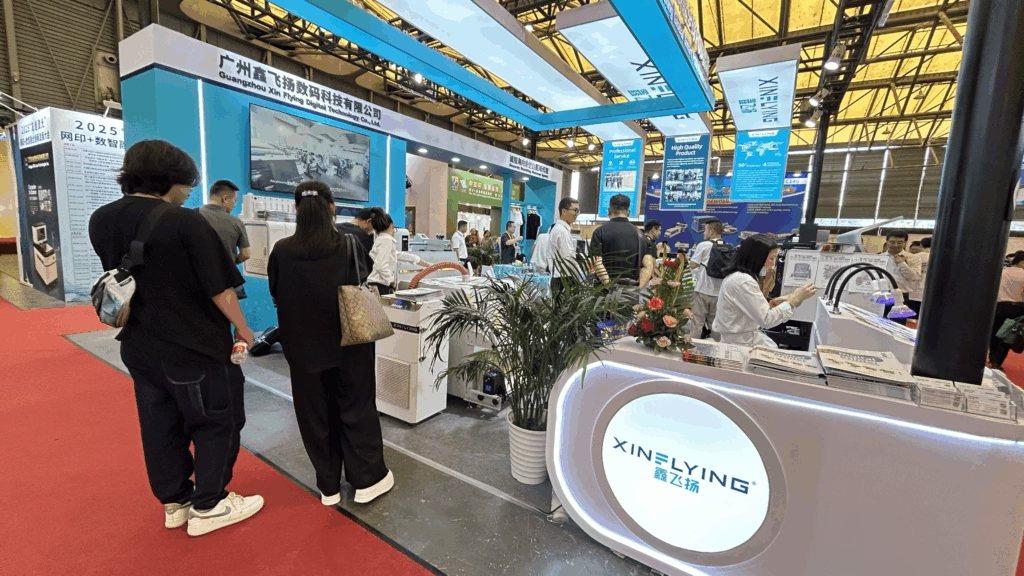

From August 7th to 9th, 2025, Xin Flying participated in the China International screen & Digital Intelligent Printing Expo 2025

with a variety of digital printer. Centering on the themes of “digitalization, green development, environmental protection and high efficiency”, the exhibition showcased advanced technologies and high-end equipment in the digital printer field, supporting the high-quality development of textile and garment enterprises.

Currently, the penetration rate of digital printer technology is gradually increasing. Its application scenarios are constantly expanding from textiles and garments to ceramics, plastic molds and labels. Meanwhile, printing technology continues to innovate and printing equipment iterates rapidly. Today, Panyu, Guangdong, China has become a major global production base for digital printer.

As a digital printer enterprise from Panyu, Guangdong, Xin Flying adopts core components such as nozzles, boards, guide rails and motors from well-known industry brands, which ensures the excellent quality and stability of its machines.

The core components of Xin Flying’s products all use Epson nozzles and imported motors. Their stability has been verified through 1,000 hours of continuous testing, and the failure rate is much lower than the industry average. However, from the perspective of digital printer buyers and textile/garment manufacturers, the key indicators of digital printer they mainly focus on are as follows:

Flexible manufacturing support: From the procurement trend of textile and garment enterprises, as personalized customization becomes a trend, market demand is shifting towards “small-batch and quick-response” production. This forces the production side to improve flexible manufacturing capabilities, so digital printer buyers are more willing to pay attention to equipment that can support their flexible production needs.

Print quality: From the perspective of technological development, buyers of digital printing equipment often pay more attention to parameters such as printing speed, print quality and color reproduction.

Operation difficulty: Electric, intelligent and energy-saving digital printer that can greatly reduce manual intervention and operation difficulty while improving production efficiency has gradually become the mainstream…

Therefore, at this exhibition, in response to the rapidly changing market and customer needs, Xin Flying launched a number of best-selling digital printer products, attracting many buyers to stop and watch. The Xin Flying digital printer booth mainly covered the following categories: high-speed direct digital printer (2-head/5-head) that break international monopoly, 3D simulated embroidery digital printer, and UV crystal label digital printer.

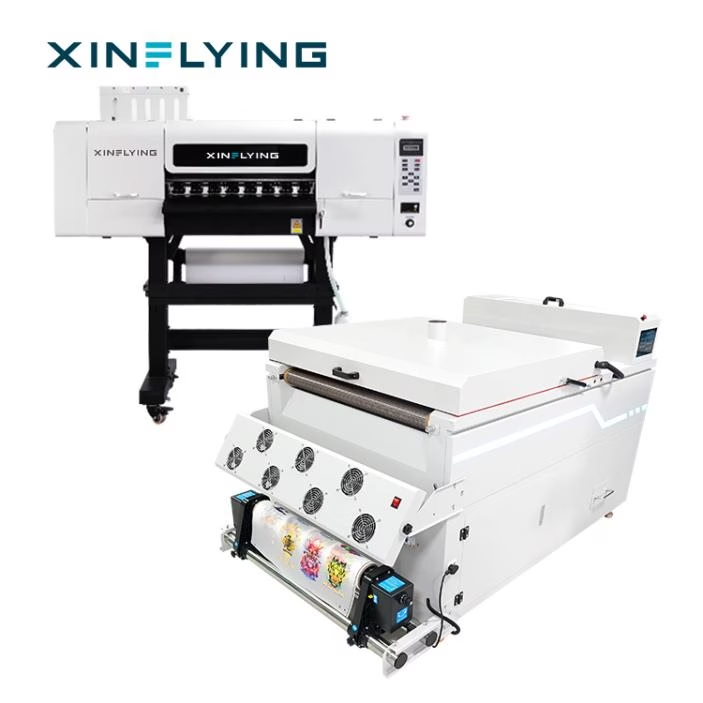

- 24’’5pcs Epson i3200-A1 Print Heads DTF Printer

Product Highlights

1、Hansen Board Card

All our printers are equipped with Hansen board cards.

The Hansen board card is deeply integrated with the hardware system of Xin Flying DTF digital printers, ensuring stable operation of the equipment under long-term and high-intensity working conditions. In the textile printing industry, different fabrics have varying requirements for printing parameters. With strong compatibility, the Hansen board card can flexibly adjust output, ensuring excellent printing results on various fabrics such as cotton, polyester, and blends, which greatly expands the equipment’s application scope.

In terms of stability and durability, the Hansen board card performs exceptionally well. Adopting military-grade design standards and undergoing rigorous testing, it has an extremely low repair rate and can adapt to the high-intensity working environment of 24/7 continuous production. This is crucial for enterprises that undertake a large number of orders and have high requirements for production continuity, as it reduces downtime caused by equipment failures. Additionally, it is equipped with user-friendly functions such as broken hole compensation. When the printhead experiences issues like clogged holes or skewed jetting, the board card can compensate for the data—neither affecting production capacity nor compromising the overall printing effect, thus saving users the cost of printhead replacement.

2、Epson i3200 Printhead: Empowering Both Printing Quality and Efficiency

Xin Flying digital printer printers adopt the Epson i3200 printhead, precisely leveraging its significant advantages in multiple dimensions including precision, color, speed, and durability to create an unparalleled printing experience for users.

(1) Precision Manufacturing for Outstanding Printing Accuracy

The Epson i3200 printhead features a high-precision nozzle arrangement, achieving an ultra-high density of 600 npi/2 rows. This precise structure allows the printhead to accurately plan the ejection path of each ink droplet within a compact space. During the printing process of digital printer, ink droplets land precisely, realizing ultra-high-precision reproduction of patterns and text without any blurring or smudging—meeting the needs of professional fields with strict requirements for printing accuracy.

(2) Variable Droplet Size for Rich Color Layers

The i3200 printhead can freely and accurately control the size of ejected ink droplets, enabling multi-gray-scale output. When printing images with rich color transitions, the printhead intelligently adjusts the droplet size based on factors such as lightness, darkness, and color saturation of different areas in the image. This intelligent droplet control effectively eliminates graininess in the image and significantly improves color saturation.

(3) Excellent Printing Speed to Meet High-Efficiency Production Needs

While ensuring printing quality, the Epson printhead also delivers excellent printing speed. For example, the effective printing width of the i3200-A1 printhead facilitates high-efficiency production, and the nozzles maintain high consistency, enabling efficient printing.

3、Automatic Printhead Cleaning: The “Smart Steward” for Stable Printing

Pain Point in Scenarios:

In DTF digital printer production, print head clogging is one of the most troublesome issues for practitioners—ink drying and impurity residues can lead to ink breakage and ink splattering, which not only ruins entire batches of printed products but also may damage the print head. The automatic print head cleaning function equipped in Xin Flying DTF digital printer acts as a “smart steward” on call 24/7, solving print head maintenance problems through automated processes and safeguarding stable production.

Product Highlights:

Negative Pressure Ink Suction Cleaning: The equipment uses a built-in negative pressure system to reversely suck ink from the bottom of the printhead, thoroughly removing dried ink residues and tiny impurities in the nozzles to prevent clogging. At the same time, the system automatically detects the ink suction pressure to ensure moderate strength—neither damaging the printhead’s piezoelectric components nor compromising the efficient removal of clogs.

Positive Pressure Flushing and Unclogging: For stubborn clogs, the system switches to positive pressure mode, injecting special cleaning fluid (or pure water) into the nozzles. It flushes the nozzle channels with gentle pressure to dissolve residual cured ink, making it especially suitable for deep cleaning after long-term shutdowns or when using high-viscosity ink.

Automatic Moisturizing and Sealing: After cleaning, the equipment automatically resets the printhead to a sealed moisturizing chamber and sprays a small amount of moisturizing fluid to form a protective film on the nozzle surface. This prevents ink from drying at the nozzles, allowing the equipment to quickly enter working condition when restarted even after being idle for several days—no need for repeated manual cleaning.

4、Imported Silent Guide Rails

The silent guide rails adopt an aerospace-grade aluminum alloy thickened nano-strip design, featuring a double-thickened structure for safety and stability. Additionally, the silent guide rails are wear-resistant, non-fading, and have anti-oxidation, anti-corrosion, and anti-rust properties, maintaining excellent performance even after long-term use.

- 3D Embroidery &DTF Integrated Printer

– The “3D Creative Engine” for Textile Decoration

As an innovative device integrating cutting-edge technology by Xin Flying, the 3D simulated embroidery DTF printer breaks the technical barriers between traditional embroidery and printing. It perfectly combines “3D tactile feel” with “vibrant colors”, bringing a disruptive solution to the textile decoration industry. Its core functional advantages can be summarized in the following four points:

Dual-mode Integration of “Embroidery + Printing”,Unlocking a New Dimension of Layered Design

Different from single-function DTF printers, this device realizes integrated operation of 3D simulated embroidery and DTF printing: First, it uses 3D simulated embroidery technology to outline pattern contours and 3D textures, creating raised tactile layers; then, it leverages DTF printing to fill in rich colors and delicate details. Whether it is gradient colors, complex patterns or brand logos, all can be accurately reproduced.

Barrier-free Adaptation to Multiple Fabrics, Covering Full-scenario Textile Needs

The device is compatible with various mainstream fabrics such as cotton, polyester, cotton blends and canvas.

Template-free & Efficient Production: Balancing “Flexibility for Small Orders” and “Mass Production for Large Orders”

Inheriting the core “template-free” feature of DTF printing, the device allows direct upload of design files for printing, eliminating the time and cost of making templates required by traditional embroidery. Customization is available even for a single piece.

Maximum Pattern Durability, Suitable for Long-term Use Scenarios

The stitches of 3D simulated embroidery are tight and firm, and will not easily come loose or deform even after repeated pulling and friction; DTF printing adopts high-quality ink that combines deeply with fabric fibers, featuring excellent wash resistance, light resistance and wear resistance. Patterns will not fade or peel off after multiple washes, and can maintain bright colors even after long-term exposure to the sun.

- 24’’3pcs UV DTF Printer Cold Transfer Application Solution

Xin Flying UV DTF Printer——Enabling Dual Breakthroughs in “Durability + Aesthetics” for Textile, Garment & Decoration Products

Pain Point in Scenarios:

Traditional crystal labels use UV ink, which makes the printed labels relatively rigid. When attached to clothing, they tend to crack after bending, limiting their application to solid surfaces (such as mugs and ceramics).

The newly launched Xin Flying UV DTF Printer adopts innovative UV ink. The printed crystal labels can be applied to clothing, hats, and shoes, and the patterns can withstand repeated bending without cracking…

Innovations of Xin Flying Crystal Label Digital Printer

Ink Formula Innovation: Abandoning traditional high-hardness UV ink, it develops flexibly improved ink. By adjusting resin components and curing systems, it retains the core advantages of UV ink (waterproof, wear-resistant, scratch-resistant) while significantly enhancing flexibility. This enables the printed crystal labels to be bendable, upgrading from “solid surface-only” to “fabric-compatible” and filling the technical gap in “personalized printing of textile-based crystal labels”.

Optimized Adhesion and Compatibility: The improved ink forms a tighter bond with fabric fibers and can stretch and contract synchronously with fabric deformation, eliminating the problem of cracking after repeated bending.

UV Curing Technology: Equipped with UV lamp curing technology, the ink quickly cures into a film upon contact with the fabric, forming a waterproof, scratch-resistant, and weather-resistant protective layer. For example, patterns printed on outdoor tents do not fade after 3 months of exposure to the sun, and cartoon images printed on children’s school bags do not peel off even after repeated friction.

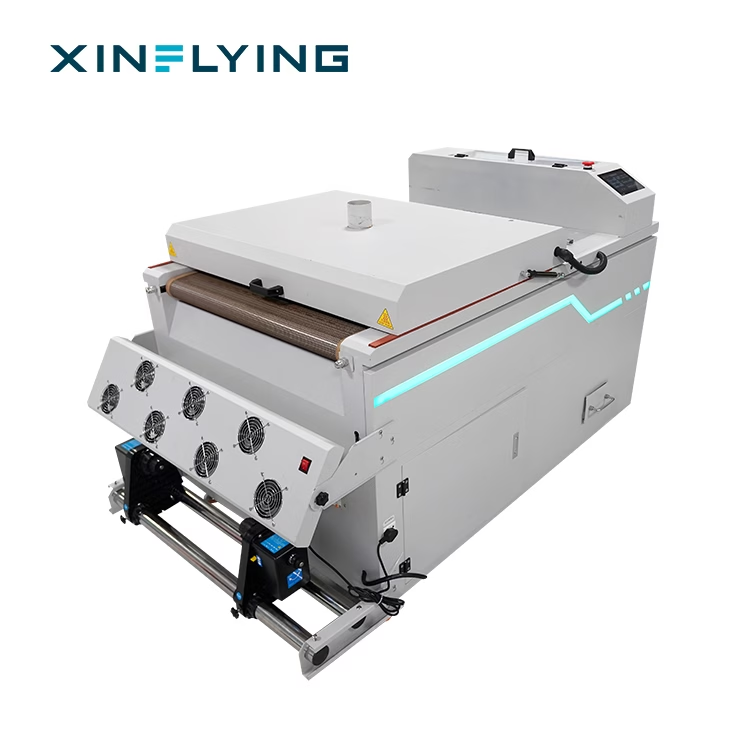

- Xin Flying Powder Shaker

Product Highlights:

It adopts quartz tube heating, which has many advantages such as high efficiency and energy saving, rapid temperature rise, uniform heating, and strong stability. Details are as follows:

High Efficiency and Energy Saving: Quartz tubes have the function of selective far-infrared radiation, no need for far-infrared coating, excellent spectral radiation matching and absorption performance, and high electrothermal conversion efficiency. They save about 30% more energy than ordinary heating elements.

Rapid Temperature Rise: Quartz tube heating belongs to infrared heating, among which short-wave infrared has a heating and cooling time of 1-3 seconds. This makes the heating process more flexible to control, enabling rapid achievement of the required temperature and fast drying/dehumidification, which can effectively improve printing efficiency.

Uniform Heating: Quartz tube heating achieves uniform heating, reducing problems such as uneven ink curing caused by temperature differences and ensuring the consistency and stability of printing quality.

Strong Stability: Quartz tubes are made of high-purity quartz, which can withstand high temperatures (up to 1200°C) and high pressures, and have good thermal shock resistance. They can withstand sudden temperature changes without cracking and maintain stable performance during long-term use.

Long Service Life: Quartz tubes have stable thermochemical properties, high insulation strength, and no pollution. Their radiation performance does not deteriorate during long-term use, they are not easily damaged, and have a long service life, which can reduce the maintenance and replacement costs of equipment.

What’s more user-friendly is that Xin Flying provides a one-stop service of “equipment + consumables + training”: free on-site installation and commissioning, hands-on teaching of operation skills, 24-hour remote technical support, and quick replacement of parts through overseas warehouses. This allows textile and garment enterprises to focus solely on receiving orders without worrying about after-sales issues.

AUTHER

During his five years of working at Xin Flying, he has accumulated rich technical support experience in the digital printer industry and possesses in-depth knowledge of digital printing equipment and sublimation printing. Relying on his professional technical competence and customer service experience, he has now helped clients in North America, Europe and the Middle East achieve excellent results.