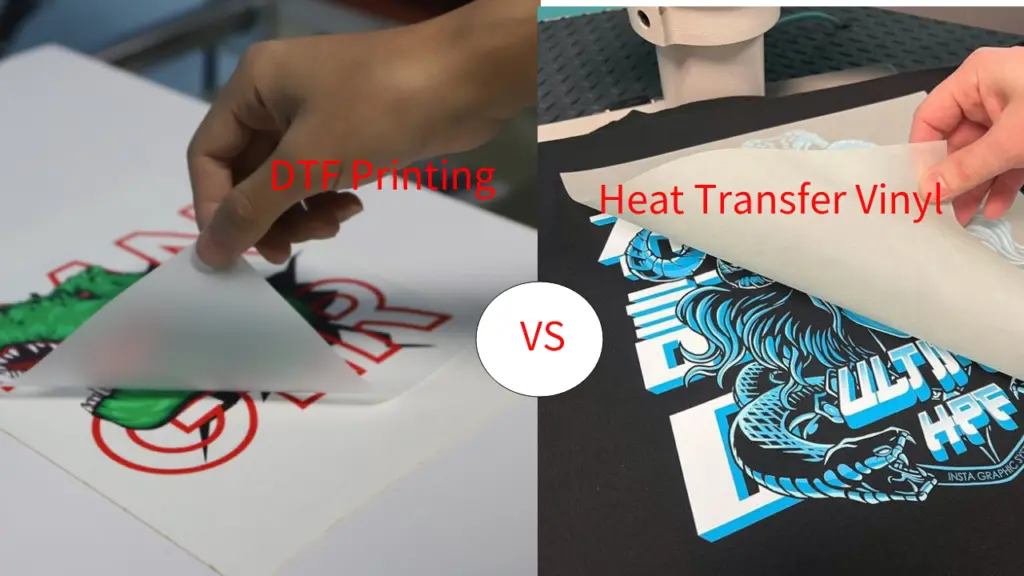

DTF Printing vs. Heat Transfer Vinyl (HTV) — which method is better for custom apparel? For small printing businesses and apparel decorators, this is an important question.

DTF (Direct-to-Film) is a relatively new technology that has gained rapid popularity in the last decade due to its vibrant colors, fine detail, and versatility. Before DTF, Heat Transfer Vinyl (HTV) dominated the custom printing industry, and it’s still widely used for simple designs and small-batch personalization.

Today, both methods are widely used and continue to transform the custom apparel market. Each has its own strengths and weaknesses. Let’s break down the differences to help you decide which is best for your needs.

What is DTF Printing?

The global direct to film printing market size was estimated at USD 2,720.0 million in 2024 and is projected to reach USD 3,920.0 million by 2030, growing at a CAGR of 6.0% from 2025 to 2030. The growth is primarily influenced by factors such as the increasing adoption of advanced printing technologies, rising demand for customized and on-demand apparel, and growing business awareness of DTF printing’s cost-effectiveness and versatility over traditional methods.(Source: Grand View Research, Direct-to-Film Printing Market Report)

Key Market Trends & Insights

- Europe accounted for 36.0% share of the overall market in 2024.

- By type, dedicated DTF printers segment accounted for the largest share of 45.0% in 2024.

- By film, cold peel film segment held a major market share in 2024.

- By end-product, t-shirts segment dominated the DTF Printing market in 2024.(Source: Grand View Research, Direct-to-Film Printing Market Report)

Market Size & Forecast

- 2024 Market Size: USD 2,720.0 Million

- 2030 Projected Market Size: USD 3,920.0 Million

- CAGR (2025-2030): 6.0%(Source: Grand View Research, Direct-to-Film Printing Market Report)

DTF printing starts by printing your design onto PET transfer film using specialized water-based inks, including white ink for base layers and CMYK for colors.

After printing, TPU hot-melt adhesive powder is applied to the wet design. The powder is then cured using heat, creating a strong bond for transferring onto fabrics with a heat press.

Key components of DTF printing include:

- DTF Printer – Specialized printers that produce vibrant, precise designs directly onto film. Xinflying offers models for both small and large-scale production.

- DTF PET Film – High-quality film with an adhesive layer, available in various sizes.

- DTF Inks – Water-based pigment inks that provide bright, durable colors.

- RIP Software – Prepares your artwork for the printer and optimizes colors, halftones, and layers.

- DTF Powder – Adhesive powder that ensures designs stick firmly to the fabric.

- Heat Press Machine – Transfers the cured design from the film to garments with controlled heat and pressure.

DTF works well on cotton, polyester, blends, dark fabrics, and even non-textile surfaces. It excels at complex designs with fine details and full-color gradients.

What is Heat Transfer Vinyl (HTV)?

HTV is a simpler printing method using vinyl sheets. Designs are cut from colored vinyl and then heat-pressed onto fabric.

Required tools and materials for HTV:

- Vinyl Sheets – Pre-cut or customizable sheets in various colors, textures, and finishes.

- Vinyl Cutter – Cuts designs from the vinyl sheet.

- Heat Press – Applies temperature and pressure to adhere the design to the garment.

- Teflon Sheet – Protects the design during heat pressing.

HTV produces long-lasting prints suitable for small batches, single-color designs, or specialty finishes like glitter and metallic textures.

Key Differences Between DTF and HTV

1. Design Flexibility

- DTF: Unlimited colors, gradients, and photorealistic images. Multiple colors printed at once on one film.

- HTV: Best for simple vector designs and solid colors. Multi-color designs require layering, increasing labor and complexity.

2. Material Compatibility

- DTF: Works on nearly all fabrics — cotton, polyester, nylon, leather, blends — and even wood, metal, or ceramic.

- HTV: Mainly cotton and polyester. Blends require careful temperature control; less versatile overall.

3. Production Efficiency

- DTF: No weeding required. Multiple designs printed on one sheet. Efficient for medium to large batch production.

- HTV: Each color and design must be cut and weeded. Labor-intensive for complex designs. Single-color, small batches are faster.

4. Durability

- DTF: Withstands 50+ washes, resists cracking and peeling, maintains flexibility.

- HTV: Typically lasts 25–30 washes. Quality varies by vinyl type; may crack over time, especially with multiple layers.

5. Feel & Appearance

- DTF: Thin, fabric-like feel. Minimal bulk, soft to touch.

- HTV: Slightly raised texture; thickness increases with layers. Specialty vinyls may feel plasticky.

6. Cost & Equipment

- DTF: Higher initial investment (printer, ink, film, powder), but lower per-unit cost for bulk orders.

- HTV: Lower startup cost (vinyl cutter + heat press), but higher per-unit labor for multi-color or complex designs.

When to Choose DTF

- Photorealistic, gradient, or complex designs

- Large or medium production volumes

- Need for maximum durability

- Diverse fabric types

- Multi-color artwork

When to Choose HTV

- Simple text or logo designs

- Small batches or personalization

- Budget-conscious setups

- Specialty finishes like glitter or metallic

- Quick single-color jobs

Is DTF Better Than HTV?

Both DTF and HTV have their place. For high-volume, detailed, and durable prints, DTF is superior. For simple, small-batch, and budget-friendly applications, HTV remains ideal.

The choice depends entirely on your business needs, design complexity, and production scale.

Choosing the Right DTF Printer

Selecting the right printer is key for your success. Xinflying DTF printers deliver vibrant colors, precise details, and stable performance across fabrics, including cotton and leather.

With technical support, training, and 24/7 online service, Xinflying helps you maximize productivity, minimize downtime, and ensure consistent, high-quality results for all printing applications.

Data Source: Grand View Research, Direct-to-Film Printing Market Report

https://www.grandviewresearch.com/industry-analysis/direct-film-printing-market-report