Nowadays, small studios prefer print-on-demand production to better cater to the needs of consumers, so Direct-to-Garment (DTG) and Direct-to-Film or Film-to-Garment (DTF) printing have attracted the attention of manufacturers who want to move ahead with personalized garments and small productions.

At first, DTG printing is the main approach for T-shirt printing and small productions, now DTF printing has been in vogue. They are both suitable for small items and personalization, such as masks or T-shirts. However, their working process and results are different, so it might be hesitant for companies to choose one of them. Here’s a brief introduction to these two printing methods.

What Is DTG Printing

Source: Pinterest

Introduction

Direct-to-garment (DTG) printing is a kind of digital printing on the fabric. A design must first be digitized into the system before it is converted into a set of printing instructions by raster image processor (RIP) software.

How Does a DTG Printer Work?

The working process of DTG printing mainly consists of four steps. The first step starts with the pre-treatment of the fabric with a special solution. This step must be completed because we will be working directly on the cloth. By doing so, the ink will be properly fixed and prevented from transferring through the fabric. The second step is heating. The fabric needs to be heated to activate the pre-treatment before printing.

After that, the fabric is placed on the printer’s platen and properly aligned. With DTG printing, you can directly print the graphic on the fabric without transferring in the third step, so the process will be shorter than with DTF printing. We can choose to apply a white mask as a base to guarantee that the ink does not blend with the color of the media despite the fact that it is unnecessary on white bases. It is also possible to decrease the use of the white mask by applying white just in certain places. After the conclusion of the above process, a final press will be required to fix the ink, and then the fabric will be all set. The process of DTG printing includes two heat treatments, so it is crucial to choose a suitable sublimation printing machine manufacturer for the printing.

Suitable for Fabric Types

In the process of DTG printing, the pigment ink must be heat-pressed to bond with the cloth, which is hard to be compatible with all fabrics. Therefore, this method is restricted to a particular spectrum of fabrics, for instance, cotton, organic cotton, combed cotton, and linen, because the water-based inks can be quickly and permanently integrated with the fabric. It is hard for the inks to adhere to the substrate with waterproof properties such as polyester. DTG printer company with cutting-edge direct-to-garment printing systems can provide full-color prints on customized T-shirts at a good price.

What Is DTF Printing

Source: Pinterest

Introduction

DTG and DTF printing both use digital inkjet technology to print graphics on the fabric in a similar way. The biggest difference is that Direct-to-Film or Film-to-Garment (DTF) printing prints the pattern onto the cloth by virtue of a transfer film.

How Does a DTF Printer Work?

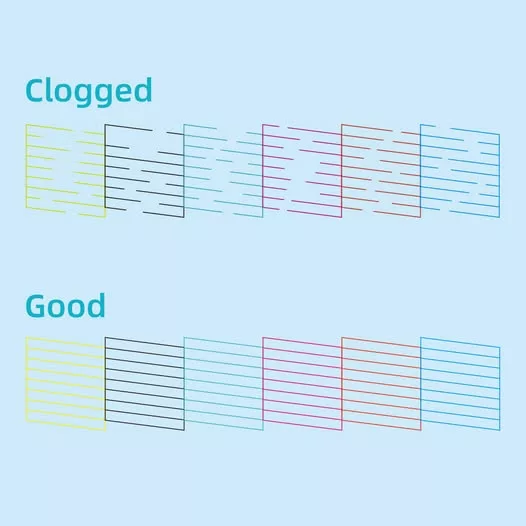

The working process of a DTF printer is different from a DTG printer. First of all, there is no need to pre-treat the garment for DTF printing because the design will be pre-printed on a film that must be transferred onto the garment, which takes longer time than DTG printing. DTF printing ink is an important material to ensure the DTF printer runs smoothly. When the ink is put onto the film, a layer of white ink must be applied on top of other color layers so that it can serve as a base when it is transferred onto the garment. The white ink is used as a foundation to preserve the bright colors in the design. DTF printing film with semi-transparent properties is able to withstand high temperatures and can be used for transfer on a variety of textile colors or types.

Right after the ink is printed on the film according to the specific pattern, DTF printing requires the use of an adhesive powder which is an important material to dry and cure ink on the film. DTF printer powder needs to be pure and has an exclusive bonding effect. On printers designed expressly for DTF, applying adhesive powder is already included in the operational program of the printer, saving you from performing it manually. At the final stage of the process, the printed film is taken and pressed into the garment.

China is a garment manufacturing power and has mature technology in printing machines, so you can consider choosing a DTF printer manufacturer from China.

Suitable for Fabric/Products Types

It is not necessary to be concerned about the fabric’s compatibility with excessive heat during DTF printing because the films with patterns are attached to the garment with a heat-melting adhesive. As a result, DTF printing can deal with any type of cloth other than cotton compared with DTG printing.

DTG vs. DTF Printer for Commercial Use

Source: Pinterest

Both kinds of printing methods may be suitable for products with similar characteristics, yet they still have their own advantages and disadvantages taking into account different production factors. So what should we consider when making a decision?

Printer Price and Ink Price

DTG printer is very expensive. A standard DTG printer can be up to $13,000. Even an entry-level DTG printer can cost $8,000. You might need a huge investment for all consumables and equipment in total.

The biggest advantage of DTF printing is its low cost. Consumables including transfer films, adhesive powder, and printer inks are cost-effective so that the expenditures can be saved and the benefits can be optimized. Furthermore, several designs can be printed on a single sheet or a roll of film to save money.

Both printing methods require a sizable amount of white ink which is astonishingly expensive, however, using competent Rip Software makes it feasible to adjust how much white ink is put in DTG depending on the base color and significantly saves expenses. For instance, neoStampa features a unique print mode for DTG that not only lets you quickly calibrate the colors, but also adjust how much white ink to use on various kinds of fabrics.

DTG printing can reduce the use of white ink on light fabrics but increase the use of white ink on dark fabrics, so its cost of ink depends. However, DTF printing transfers the graphic to the garment through a film, so the amount of ink will not vary and its cost remains the same for either light clothes or dark clothes.

Varieties of Your Product

The printing effect between the DTG printer and the DTF printer is quite different. In DTG printing, the drawing and inks are mixed with the fabric and therefore constitute a rougher and more base-like feel, but it can keep the soft handle of the cotton. Besides, the clothes can also remain as breathable as possible. While in DTF printing, the graphic of the T-shirt looks plastic and shinier because of the fixing powder, and its pictures are less combined with the fabric. As a result, the picture looks higher quality in colors because the colors are not affected by the base color.

DTG can only be used to print on cotton, but DTF can be used to print on a variety of materials. DTF may be a better option if you want the adaptability to print on any fabric or item of clothing. In addition, the transfer films can be applied to other small things, such as cups, thermos flasks, and signboards. You can try more possibilities after consulting with the DTF printer supplier.

Both DTG and DTF printing use CMYK (Cyan, Magenta, Yellow, Black) to deliver color vibrancy on a physical medium. They can have good color blending properties on the fabric and duplicate the gradient changes and subtle differences in the graphic.

Quantity & Productivity

Source: Pinterest

As DTG printing prints designs line by line, it is the slower printing option. With an entry-level DTG printer, you can print about 20 T-shirts per hour, excluding the pre-treatment of the shirts. When the DTG printing machines are all set in a shop, a team of two can finish the whole process of printing and produce 6-7 shirts per hour.

The biggest benefit of DTG printing is its capacity to produce intricate graphics in a variety of colors at a fast printing speed. It has a short preparation time. If you have pretreated garments and get them a heat press, then you can line up them and start printing. This printing method works well with small-scale customers who order fewer than 30 shirts with customized prints.

DTF might be more appropriate for small-scale printing if you want products with good colors and a small investment. On the contrary, DTG now includes more adaptable printing equipment with a variety of plates and procedures, allowing for quicker and more flexible printing. Multiple graphics can be printed on one single transfer film, which reduces a lot of production times. The printed films still need to be cut and separated manually, but DTG machines permit larger and faster output and are far more versatile than DTF. So, it’s crucial to understand the production scale of each firm.

Conclusion

Here we brief you on the main working process of DTG and DTF printing and their differences. Although DTF printing appears to surpass DTG printing, they have disparate functions and applications. In conclusion, you can choose the digital textile printer manufacturer that is best suited for your cost, product variety, and quantity. The above introduction can aid in your decision-making and provide a broad perspective.