Product Highlights:

1.Even and consistent spray ensures high-quality pretreatment results.

2.Open spray design allows for easy adjustment and customization of spray settings.

3.Suitable for multiple fabric types, making it versatile for different printing needs.

4.Improved print durability by providing an optimal base for ink adhesion.

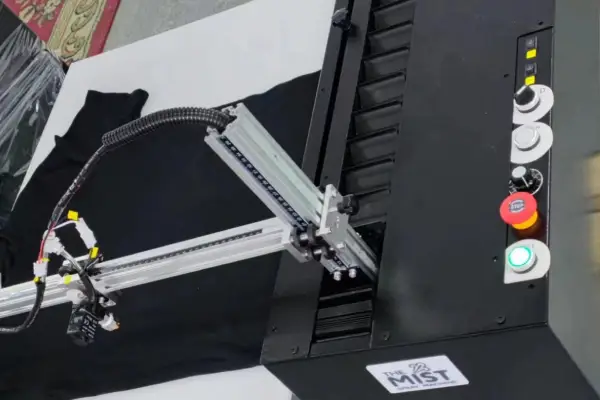

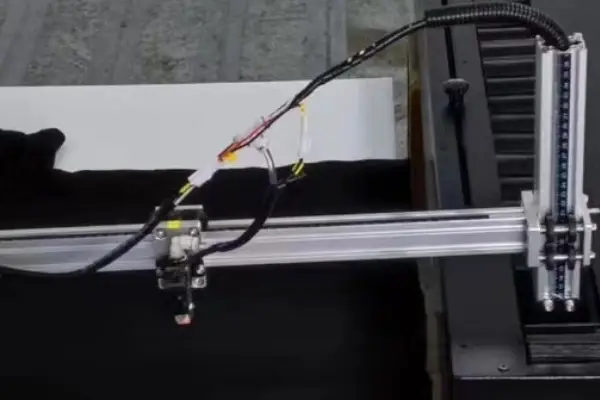

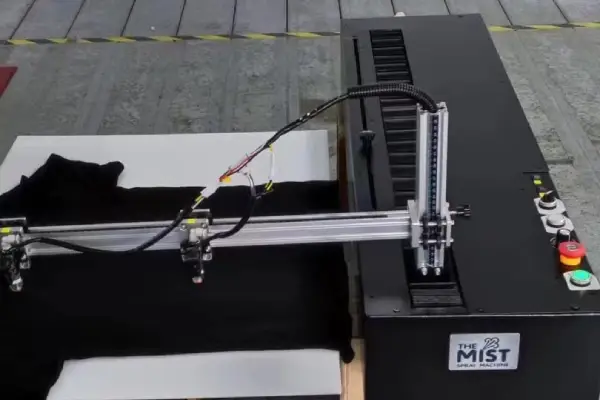

Open spray arm design with stable linear rail structure, allowing smooth movement and uniform pre-treatment spraying across the fabric surface.

High-precision spray nozzle mounted on an adjustable aluminum beam, ensuring accurate spray positioning and consistent liquid distribution.

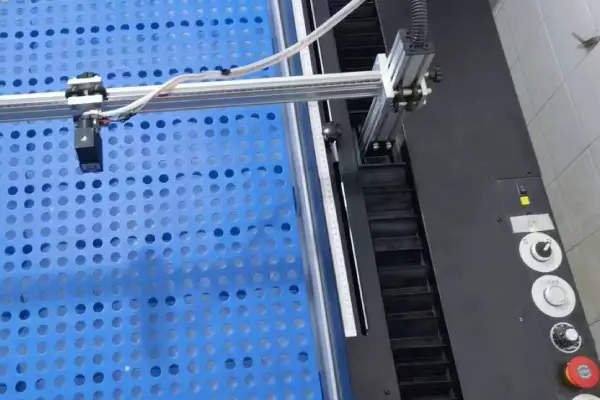

Perforated working platform designed for efficient absorption and even penetration of pre-treatment solution, improving ink adhesion and print quality.

Integrated spray system with easy-access control buttons, supporting stable operation and efficient pre-treatment processing for DTG printing.

| Model | XF-7090 |

|---|---|

| Printing Size | 70x90 |

| Voltage | 220V/110V(Optional) |

| Spray Pressure |

Adjustable spray pressure based on fabric absorbency. |

| Power | 150W |

| Spray Flow Rate | 13-100ml(Adjustable) |

| Package Size | L135xW48xH32CM |

| Net Weight | 38KG |

| Gross Weight | 48KG |

Create or upload your artwork in the design software.

Spray the pretreatment solution evenly onto the garment for better color brightness and adhesion.

Place the garment flat on the platen and let the DTG printer print the design directly onto the fabric.

Use a heat press or dryer to cure the ink and ensure durability.

The garment is ready with a vibrant, long-lasting print.

Q1: How do I adjust the spray settings on the XF-7090?

A: You can adjust the spray volume and pressure based on the fabric type and the desired amount of pretreatment. Fine-tuning these settings ensures even coverage for the best printing results.

Q2: Can the XF-7090 be used for all fabric types?

A: Yes, the XF-7090 is versatile and can be used for a wide range of fabrics including cotton, polyester, and blends. Just adjust the settings to match the fabric requirements.

Q3: Is the XF-7090 machine easy to maintain?

A: Yes, it’s designed for easy maintenance. Regular cleaning of the spray nozzles and occasional servicing will ensure smooth operation and longevity.

Q4: What is the recommended drying time after pretreatment?

A: The drying time depends on the fabric type and the amount of pretreatment applied. Generally, it takes around 10–15 minutes for proper drying, but it’s recommended to check the fabric for dryness before printing.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.