PET Film

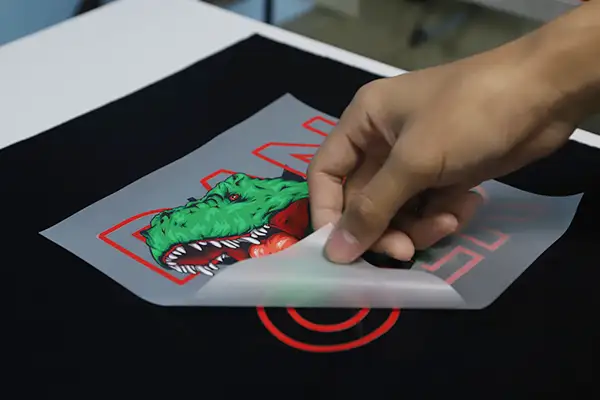

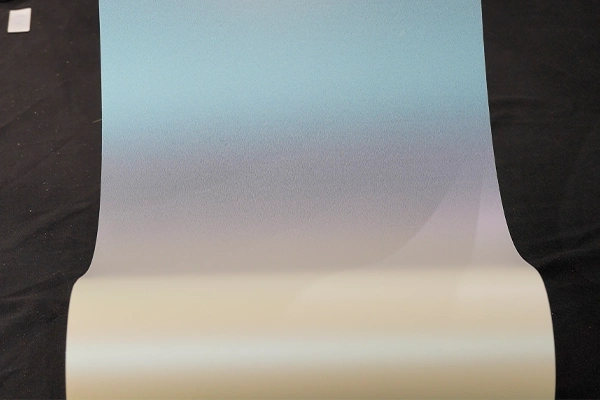

Various sizes of roll format heat transfer sheets from the DTF film manufacturer is suitable for all kinds of textile and is compatible with both hot-peel and cold peel depending on your DTF printer temperature.

Parameter

Width:30cm / 42cm / 60cm

Quantity:100㎡ / Roll

Thickness:75μm