Whether you are new to DTF printing or looking to upgrade your current setup, we are here to assist you every step of the way.

In this blog, we will provide you with expert advice, industry knowledge, and recommendations to help you make an informed decision. Besides, we aim to empower you with the necessary information to choose the ideal DTF printer that will maximize your productivity and deliver outstanding print quality. Let’s dive into the world of DTF printing and find the perfect solution for your printing business.

Best DTF Printers based on Various Business Scenarios

When it comes to choosing the best DTF printer for your specific business needs, it’s essential to consider factors such as print quality, reliability, ease of use, and affordability. Here are some recommendations for the best DTF printers in different business scenarios:

Best DTF Printer for Startup: 370mm

Startups require printers that offer a balance between affordability, ease of use, and print quality. As startups typically have smaller volumes, a suitable DTF printer would be:

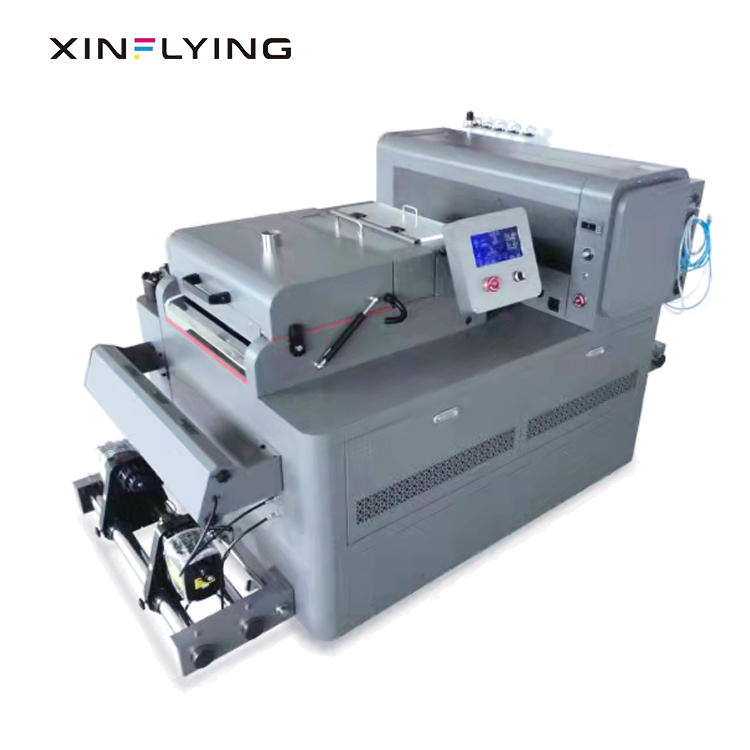

12 Inch All-in-One DTF Printer(XF-480)

| DTF Printer Solution for Startup | 12 Inch All-in-One DTF Printer(XF-480) |

| Productivity | 4㎡/h (6 Pass) |

| Printing Width | 0-370mm |

| Printhead | 2* Epson XP600 |

| Dimension | 1946 x 1112 x 1157mm |

This all-in-one printer offers impressive print quality, user-friendly operation, and low maintenance requirements. It is a budget-friendly choice for startups looking to enter the garment printing market with smaller volumes. It can be used for various demanding clothing applications, as well as brand customization like printing logos, changing colors, and upgrading smart control.

Best DTF Printer for Small Business: 370mm or 600mm

Small businesses often require DTF printers that can handle growing customer demands, offer versatility, and deliver consistent print quality. Here’s a recommendation for a DTF printer suitable for small businesses:

12 Inch All-in-One DTF Printer(XF-480 Plus)

| DTF Printer Solution for Small Business | 12 Inch All-in-One DTF Printer(XF-480 Plus) |

| Productivity | 9㎡/h (6 Pass) |

| Printing Width | 0-370mm |

| Printhead | 2* Epson I3200-A1 (Optional 4720) |

| Dimension | 2100 x 1112 x 1209mm |

This DTF printer is an upgraded version of XF-480 supporting more colors and a higher efficiency printhead. It suits for small businesses with numerous applications on materials like nylon, chemical fiber, cotton, leather, etc. It comes with a built-in powder shaking machine that’s different from the normal separated ones in the market. It saves a lot of space and cost while still maintaining an exclusive performance to spreading evenly.

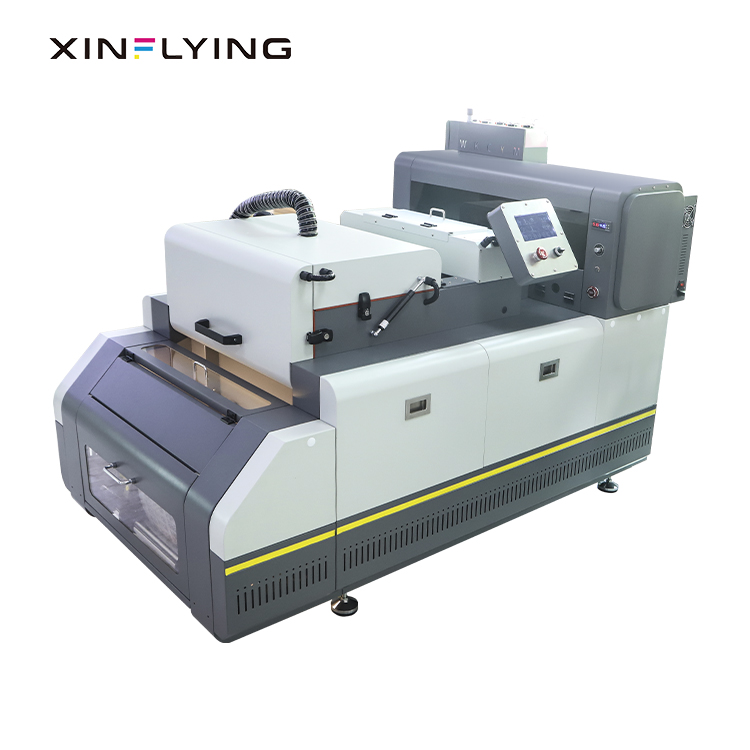

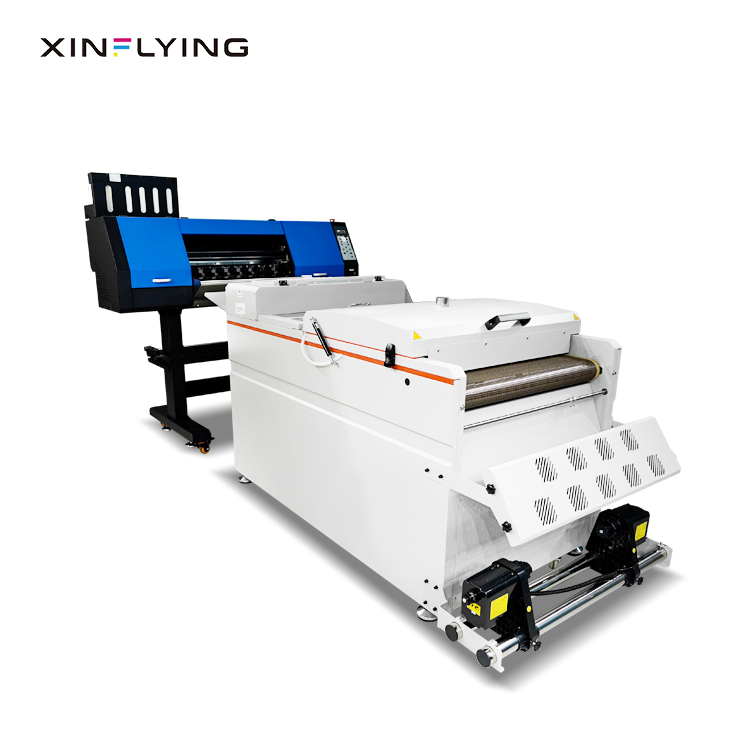

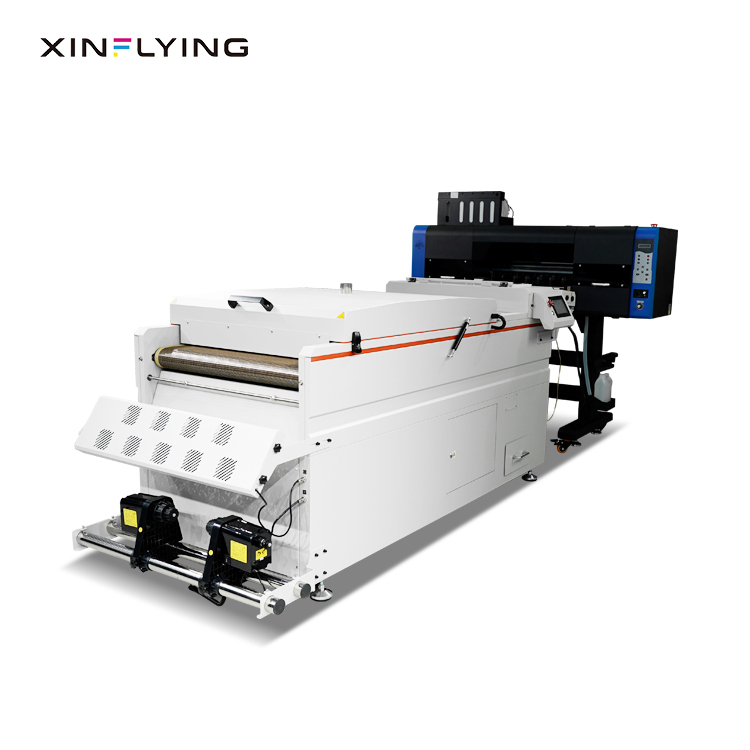

24 Inch 2 heads DTF Printer(E602+H650)

| DTF Printer Solution for Small Business | 24 Inch 2 heads DTF Printer(E602+H650) |

| Productivity | 12㎡/h (4 Pass) |

| Printing Width | 0-600mm |

| Printhead | 2* Epson I3200-A1 (Optional 4720) |

| Dimension | 1660 x 750 x 1620mm |

The updated version of E602+H650 with more efficient drying & curing process. It offers high precision, efficiency, and high-resolution colors, and is easy to operate & maintain. With exceptional print speeds and a wide color gamut, it ensures vibrant and high-quality prints, perfect for small or medium businesses catering to on-demand orders.

Best DTF Printer for Mass Printing: 600mm or 1200mm

For businesses focused on mass production with high printing volumes, industrial-grade DTF printers are required. These printers should offer exceptional speed, reliability, and superior print quality. Here’s a recommendation for a DTF printer suitable for mass printing:

24 Inch 4 Heads DTF Printer(T604+H6501)

| DTF Printer Solution for Small Business | 24 Inch 4 Heads DTF Printer(T604+H6501) |

| Productivity | 22㎡/h (4 Pass) |

| Printing Width | 0-600mm |

| Printhead | 4* Epson I3200-A1 (Optional 4720) |

| Dimension | 1820 x 820 x 1620mm |

Designed specifically for high productivity and mass printing, this DTF printer is built with fast productivity to handle extensive printing applications in a short time, such as polyester, cotton, cotton linen, etc. With fully automatic processes ensuring high functionality and less labor cost, It is the perfect choice for businesses focused on large-scale production and customization.

48 Inch 4 Heads DTF Printer(XF-1304+1300)

| DTF Printer Solution for Small Business | 48 Inch 4 Heads DTF Printer(XF-1304+1300) |

| Productivity | 25㎡/h (4 Pass) |

| Printing Width | 0-1200mm |

| Printhead | 4* Epson I3200-A1 (Optional 4720) |

| Dimension | 2485 x 955 x 1573mm |

With its high-speed production capability and outstanding print quality, this printer is a reliable option for mass printing. It offers high precision, efficiency, and high-resolution colors, and is easy to operate & maintain. This printer has two kinds of powder shaking machines with different powder and efficiency for you to choose from. Besides, its versatility in printing on various fabric types and excellent color accuracy make it suitable for businesses with high production output demands.

Keep in mind that while these recommendations are suitable for specific scenarios, it’s essential to assess your business requirements, budget, growth potential, and consult with industry experts or reputable suppliers to make an informed decision. By choosing the best DTF printer for your business, you can optimize your printing operations, deliver high-quality products, and drive success in your industry.

What is DTF Printing?

DTF (Direct-to-Film) printing is a revolutionary printing method that has gained popularity in recent years. Unlike traditional printing techniques, such as screen printing or direct-to-garment (DTG) printing, DTF printing offers unique advantages and capabilities.

With its versatility, DTF printing can be used on a wide range of materials, including cotton, polyester, leather, and more. The combination of DTF ink and powder creates a durable bond with the fabric, resulting in prints that withstand washing, stretching, and general wear and tear. DTF printing offers high-resolution and intricate design reproduction, ensuring sharp details and vibrant colors on the final print.

DTF vs DTG

Here is the DTF vs DTF comprasion chart:

| Type | DTG Printing | DTF Printing |

| Fabric Suitability | Best suited for 100% cotton or cotton-blend fabrics, may vary on other materials. | Works well on various fabric types, including cotton, polyester, blends, and leather. |

| Printing on Dark Fabrics | Requires a white ink base layer for printing on dark fabrics, which can result in thicker prints. | Eliminates the need for white ink layer, making it suitable for printing on dark-colored fabrics. |

| Color Vibrancy | Also provides good color reproduction, ideal for photorealistic images and gradients. | Offers excellent color reproduction and vibrant prints. |

| Durability | Provides good washability, but durability may vary depending on fabric and ink used. | DTF prints are known for their durability and can withstand washing and regular wear. |

| Production Volume | Ideal for on-demand or short-run printing capabilitiesAbout 6 hours to print 100 shirts | Suitable for larger print runs or detailed designs that require vibrant colors.About 2 hours to print 100 shirts |

| Printer Cost | About $3k to $40k | About $20k to $500k |

When it comes to garment printing, two popular methods that often come into consideration are DTF (Direct-to-Film) printing and DTG (Direct-to-Garment) printing. Let’s compare the advantages and disadvantages of each method:

DTF Printing

Advantages:

- Versatility: DTF printing is highly versatile and can be used on a wide range of fabrics, including cotton, polyester, blends, and even leather.

- Vibrant Colors: DTF printing offers excellent color reproduction and the ability to achieve vibrant and detailed prints with a wide color gamut.

- Durability: DTF prints are known for their durability. The combination of DTF ink and powder creates a long-lasting bond with the fabric, ensuring the prints withstand washing and regular wear.

Disadvantages:

- Setup and Pre-Treatment: DTF printing requires preparing the design on a DTF film and applying a layer of DTF powder. This additional step adds to the setup time compared to DTG printing.

- White Ink Limitation: DTF printing requires a white base layer for printing on dark-colored fabrics, which can result in a thicker print feel compared to DTG, depending on the design and chosen materials.

When to use DTF printing:

DTF printing is preferred when printing on dark-colored fabrics, as it eliminates the need for white ink under the design. It is suitable for larger print runs or detailed designs that require vibrant colors and good washability. DTF printing is often chosen for its versatility in printing on various fabric types and its excellent durability.

DTG Printing

Advantages:

- High Detail and Resolution: DTG printing offers exceptional detail and resolution, making it ideal for intricate designs, gradients, and photorealistic images.

- No Setup Time: DTG printers are ready to print immediately, without the need for additional preparation steps like DTF printing.

- Soft Feel: DTG prints have a softer feel compared to DTF prints, as DTG inks are directly absorbed into the fabric.

Disadvantages:

- Limited Fabric Compatibility: DTG printing works best on 100% cotton or cotton-blend fabrics, and its performance might vary on other materials.

- Continuous Printer Maintenance: DTG printers require regular maintenance, including nozzle cleanings and periodic ink flushing, to ensure optimal performance and print quality.

When to use DTG printing:

DTG printing is preferred for on-demand or short-run printing, as it does not require the setup time associated with DTF printing. It is ideal for highly detailed designs, fine artwork, or intricate patterns requiring a soft-hand feel on lighter-colored garments. DTG printing is commonly used in small print shops, boutique apparel businesses, or for personal customizations.

Ultimately, the choice between DTF and DTG printing methods depends on your specific requirements, such as fabric compatibility, design complexity, desired print quality, and production volume. Evaluating these factors will help you determine the most suitable printing method for your business needs.

DTF Printer Supplies

To achieve successful DTF prints, three main components are crucial:

DTF Ink

Specifically designed for DTF printing, this ink is formulated to adhere to the DTF film and transfer easily onto fabrics. It boasts excellent color saturation and is available in a wide range of shades.

DTF Film

This transparent film acts as the transfer medium, holding the printed design and facilitating its transfer onto the fabric. DTF films are available in various sizes to accommodate different printing needs.

DTF Powder

The DTF powder is applied to the printed design on the film before transferring it to the fabric. This powder ensures proper adhesion and enhances the color brilliance and longevity of the print.

How Does The Best Commercial DTF Printer Work?

Here are four main steps:

- Design on the RIP software

- Print the design on the transfer film

- Apply the DTF powder

- Heat press/transfer

Step #1: Design on the RIP software

Organize your design on the computer and get ready to print. Xin Flying provides RIP software which helps in improving this setting.

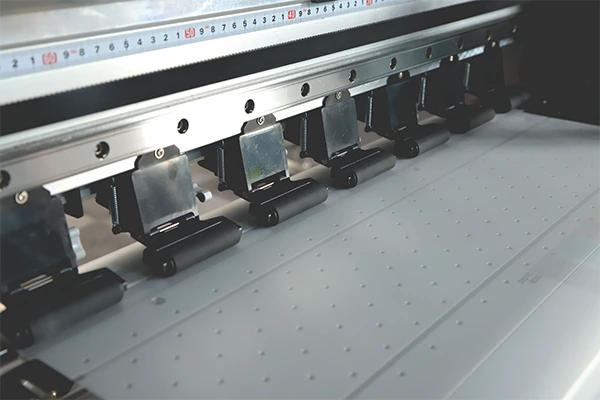

Step #2: Print the design on the transfer film

Put the PET film into the printer trays & print the entire image on it. Then, using the color settings in the printer, print the required image on the white layer.

Step #3: Cure ink with the powder

With powder shaker machine, hot-melt powder can be applied evenly on the PET film while the print is still wet.

Step #4: Heat press to transfer

Place the DTF PET film on the top of substrate and press it with a heat press machine to transfer your pattern.

DTF Printing Applications

DTF (Direct-to-Film) printing offers a wide range of applications, making it a versatile choice for various industries and businesses. Here are some of the key areas where DTF printing excels:

1. Apparel Manufacturing

DTF printing is particularly popular in the apparel industry. It allows for high-quality and durable prints on fabrics, including t-shirts, hoodies, activewear, and more. DTF printing offers the flexibility to print on both light and dark-colored garments without compromising the design’s vibrancy.

2. Custom Merchandise

With DTF printing, businesses can create personalized and custom merchandise for their customers. This includes items like tote bags, hats, accessories, and even shoes. The ability to print intricate designs and vibrant colors opens up countless opportunities for unique and eye-catching merchandise.

3. Promotional Items

DTF printing offers a cost-effective solution for producing promotional items with complex designs. Companies can create branded products like pens, mugs, keychains, and phone cases, ensuring their logo and messaging stand out to leave a lasting impression on customers.

4. Sports and Team Apparel

DTF printing is an excellent choice for producing sports jerseys, team uniforms, and fan merchandise. The durability and vibrant colors of DTF prints make them ideal for sports teams, ensuring their apparel can withstand rigorous use and capture attention on the field or in the stands.

5. Fashion and Design

DTF printing opens endless possibilities for fashion designers and artists looking to express their creativity. It enables the printing of intricate patterns, detailed graphics, and photo-realistic images on fabrics, allowing designers to bring their visions to life.

Examples of successful DTF printing projects span industries like clothing brands, promotional companies, and creative startups. These projects showcase the versatility and capabilities of DTF printing, highlighting the exceptional print quality and lasting durability it offers. Some examples include:

- Custom-designed t-shirts featuring intricate artwork and bold colors for a clothing brand.

- Branded merchandise like tote bags and accessories with elaborate designs for a promotional campaign.

- Sports team uniforms with sharp graphics and vibrant team colors for enhanced visibility and brand recognition.

- Fashion garments with photorealistic images and unique patterns, capturing attention on the runway or in retail settings.

These examples demonstrate how DTF printing can elevate the quality and impact of various products, enabling businesses to stand out in competitive markets. As we continue our exploration, we will delve deeper into the features of DTF printers, helping you select the ideal printer for your specific applications.

Factors to Consider when Choosing the DTF Printer

When it comes to selecting the right DTF (Direct-to-Film) printer for your business, several essential factors need to be considered. Each factor plays a crucial role in determining the suitability of the printer for specific needs. Here are some key factors to keep in mind before making a purchase:

1. Print Quality

One of the most crucial considerations is print quality. Evaluate the printer’s resolution capabilities, color reproduction, and the level of detail it can achieve. Look for a printer that can consistently produce sharp, vibrant, and high-resolution prints to ensure customer satisfaction.

2. Printing Speed

Consider the speed at which the printer can produce prints. Depending on your volume requirements, you may prioritize a faster printing speed. However, it’s important to maintain a balance between speed and print quality, as faster printing may sometimes compromise on detailed or intricate designs.

3. Durability and Longevity

The durability of the printer is important to ensure its longevity and reliable performance over time. Consider factors such as build quality, robustness, and the ability to handle continuous printing without significant wear and tear. Opt for a printer that is known for its reliability and has a solid reputation in the industry.

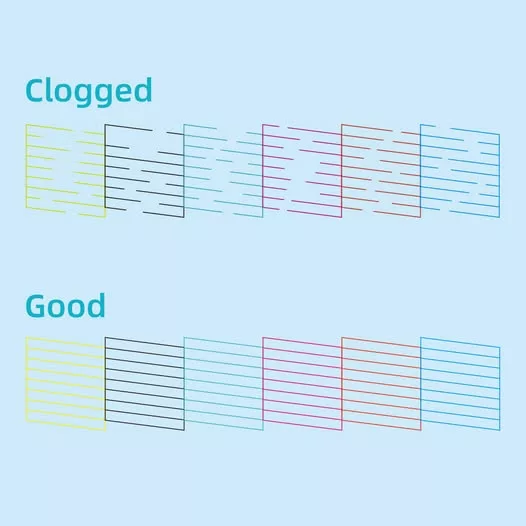

4. Maintenance Requirements

Understand the maintenance requirements for the printer you are considering. Regular maintenance, such as printhead cleaning, ink flushing, and replacing consumables, is necessary for optimal performance. Evaluate the ease of maintenance and whether the printer requires any specialized knowledge or technical expertise for troubleshooting common issues.

5. Cost-effectiveness

Compare the total cost of ownership, including the initial investment, ink and media expenses, and ongoing maintenance costs. Consider the printer’s efficiency in ink consumption and the availability and affordability of DTF inks and films. You want to ensure that the printer delivers value for money and fits within your budget.

Tips to Select the Most Suitable DTF Printer

a. Evaluate your business requirements: Understand your printing needs, including volume, types of fabrics or substrates, and desired print quality. This will help you narrow down the features and specifications required in a DTF printer.

b. Research and read reviews: Take the time to research different DTF printer models and read reviews from reliable sources. Pay attention to feedback on print quality, reliability, and customer support. Real-world user experiences can provide valuable insights for making an informed decision.

c. Request print samples: If possible, request print samples from the printer manufacturer or supplier. Examining and comparing the actual printed results can give you a firsthand experience of the print quality, color vibrancy, and level of detail achievable with the printer.

d. Consider technical support and warranty: Look for a printer that comes with comprehensive technical support and a warranty that suits your needs. Reliable customer support and a solid warranty can provide peace of mind in case of potential issues or required repairs.

e. Seek recommendations and expert advice: Consult with industry experts, printing professionals, or business owners who have experience with DTF printing. Their insights and recommendations can be invaluable in identifying the most suitable printer for your specific business needs.

Remember, choosing the right DTF printer is a critical decision that can significantly impact your printing operations and the quality of your prints. By carefully considering these factors and following the tips provided, you can make an informed decision that aligns with your business goals and ensures a successful DTF printing venture.

Conclusion

In conclusion, DTF printing has the potential to revolutionize the way businesses approach garment printing. Its ability to produce high-quality, vibrant, and durable prints opens up numerous opportunities for creative expression and brand promotion.

We encourage you to further explore the world of DTF printing, consider its adoption in their own businesses, and unlock the benefits and possibilities it offers.

As technology continues to advance and DTF printing evolves, staying informed and embracing these innovative printing techniques can give businesses a competitive edge in the market. So, why wait? Start exploring DTF printing today and unlock its potential for your business!