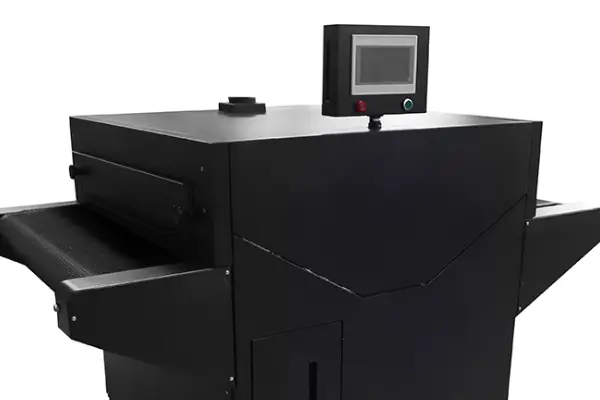

Product Highlights:

1.Adjustable temperature and speed for precise control over drying conditions.

2.High-speed drying significantly reduces production time.

3.Uniform drying ensures consistent print quality on all fabrics.

4.Durable design built for long-term, high-volume usage.

Open spray arm design with stable linear rail structure, allowing smooth movement and uniform pre-treatment spraying across the fabric surface.

High-precision spray nozzle mounted on an adjustable aluminum beam, ensuring accurate spray positioning and consistent liquid distribution.

Perforated working platform designed for efficient absorption and even penetration of pre-treatment solution, improving ink adhesion and print quality.

Integrated spray system with easy-access control buttons, supporting stable operation and efficient pre-treatment processing for DTG printing.

| Model | XF-DG80E-1 |

|---|---|

| Power Supply |

3 P 220-240V/380V-415V, 50/60hz |

| Maximum Power Consumption | 8Kw/h |

| Diameter of Exhaust Pipe | 10cm |

| Transmission Speed | about 30s-12 min |

| Conveyor Belt Width | 80cm |

| Effective Oven Length | 100cm |

| Machine Size | 180cmX110cmX116cm |

Create or upload your artwork in the design software.

Spray the pretreatment solution evenly onto the garment for better color brightness and adhesion.

Place the garment flat on the platen and let the DTG printer print the design directly onto the fabric.

Use a heat press or dryer to cure the ink and ensure durability.

The garment is ready with a vibrant, long-lasting print.

Q1: How do I set the temperature and speed on the XF-DG80E-1 Tunnel Dryer?

A: The temperature and conveyor speed should be set based on the material and the type of printing process used.

Q2: Can I dry different types of fabrics in the XF-DG80E-1?

A: Yes, the XF-DG80E-1 is suitable for drying various fabric types, including cotton, polyester, and other materials used in DTG printing.

Q3: How fast is the drying process with the XF-DG80E-1 Tunnel Dryer?

A: The drying process is fast, with typical drying time taking only a few minutes, depending on fabric thickness and settings. The high-speed drying system ensures efficient results for large-scale production.

Q4: Is the XF-DG80E-1 energy-efficient?

A: Yes, the XF-DG80E-1 Tunnel Dryer is designed to be energy-efficient, using advanced heat circulation technology to minimize energy consumption while providing consistent and fast drying.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.